FILM, FOAM AND ANTISTATIC BAGS

ESD (electrostatic discharge) packaging is made using antistatic films, foams or bags. It is a very useful type of packaging to protect electronic devices and other products sensitive to static electricity discharges and electrostatic fields that may be generated during their manufacture, transport or storage.

Description of protective antistatic bags

The various forms of ESD (electrostatic discharge) packaging, which include a wide variety of antistatic films, foams and bags, are designed to protect sensitive electronic devices from static electricity discharges or harmful electrostatic fields. All bags, films and foams have the “ESD warning” symbol marked.

They are also marked with the batch number to improve their traceability, while the semi-transparency or full transparency of the films facilitates the identification of their content. The degree of transparency that the film, foam or antistatic bags have depends on the material with which they are made, which can be pink LDPE (Low Density Polyethylene) that dissipates electricity or a layer metallized with aluminum between layers of polyester and polyethylene, always being a material free of amines.

All available antistatic bags have a hermetic closure system that serves for vacuum packaging, such as zip closure, adhesive closure or heat closure. These bags, in the same way as film or foam, if they completely cover a product, they protect it from any type of electromagnetic wave, generating protection through the Faraday effect.

There are three main types of ESD products: dissipative, shielding and conductive. Dissipative products, generally pink in colour, are made of treated polymers, in this case polyethylene, which allow for the slow and safe dissipation of electrostatic charges. Shielding products, silver in colour, are composed of metallic aluminium layers that create a barrier against discharges, while conductive products, black in colour, are made of highly conductive materials, carbon in our products, which allow for the rapid dispersion of electrostatic charges to prevent dangerous build-up.

Applications

The different types of antistatic packaging (bags, film or foams) have a great applicability especially in sectors where electronic devices vulnerable to external electromagnetic forces and fields are used, transported and stored. These areas in which antistatic bags can be useful are:

- The electronics and computer industry (PCs, televisions, mobile phones, etc.).

- The automotive industry (all kinds of electronic parts of vehicles).

- Producers of cables and cable assemblies.

- The chemical industry (for example chemical solutions with electrolytes susceptible to alterations by EM fields)

- Producers of EMS (electronic manufacturing services) or PCB (printed circuit boards)

- The cosmetics industry (For sprays susceptible to electrostatic discharge explosions)

Specifications

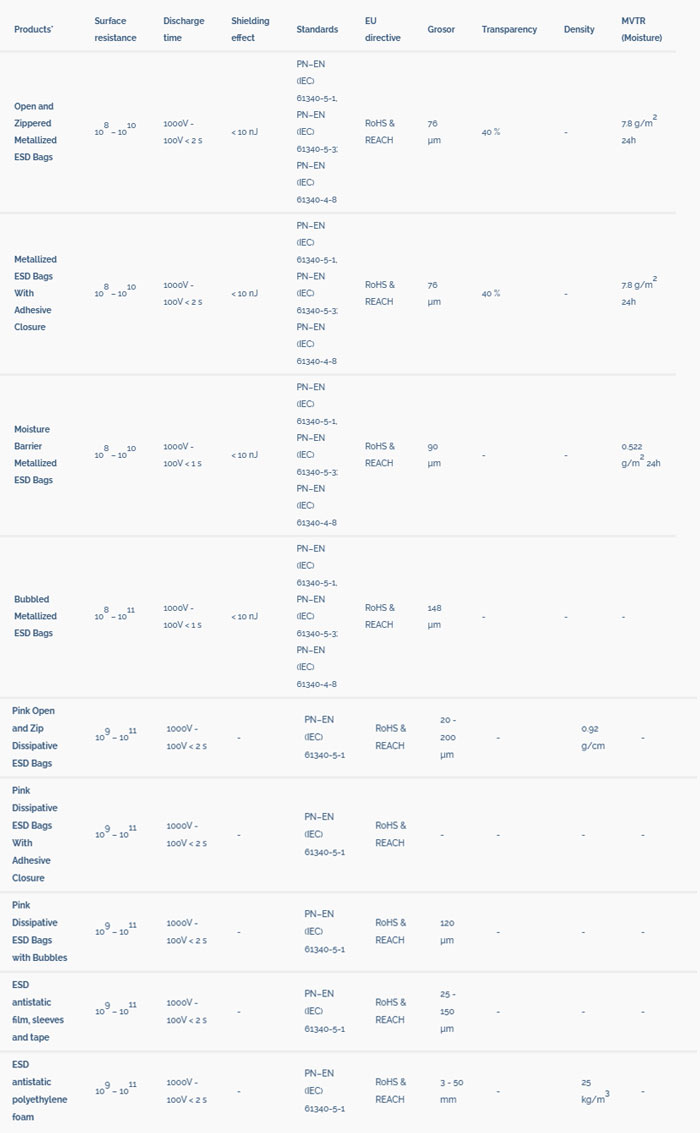

Different types of antistatic packaging have different technical characteristics depending on the way they are used.

Below are the specifications of the different products we offer, differentiated into two large groups: the metallic ESD packaging and the dissipative antistatic packaging (pink).

*If you want more technical information, we can offer it to you by contacting us. In addition to the products shown in the table we can also offer you permanent dissipative antistatic bags, biodegradable antistatic bags, antistatic garbage bags and antistatic gusseted bags. In the same way, if you wish, we can provide you with the corresponding technical information.

Supplies

To know the dimensions available for each product, to make any other question about the products, or to request a quote, contact us.

You may also be interested in

See other types of Films and bags, VCI Anticorrosion products, Aluminium, ESD Antistatic and High Resistance products.

CONTACT US

We are characterised by our attention, flexibility, speed and delivery reliability. The best personalised service with a reliable supplier for regular deliveries.