How WarmMark temperature indicators work and why they are key in the cold chain

WarmMark temperature indicators have established themselves as an effective solution for temperature control in the transport and storage of sensitive products. These single-use devices provide visual and irreversible detection of any temperature deviations that could compromise the quality, safety or efficacy of products during logistics. They work by accumulating time above a defined temperature threshold, providing objective evidence for decision-making in the supply chain.

Maintaining the right temperature during transport and storage is a constant challenge in sectors such as pharmaceuticals, food, chemicals and biotechnology. Temperature variations can occur at multiple points along the route: in lorries, distribution centres, warehouses or during the last mile.

Given this scenario, passive monitoring devices have gained prominence as a complement to traditional electronic systems. WarmMark responds to this need with simple, reliable and low-cost indicators that allow verification of whether a product has been exposed to unacceptable temperatures.

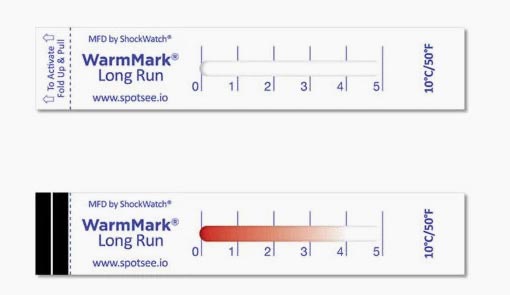

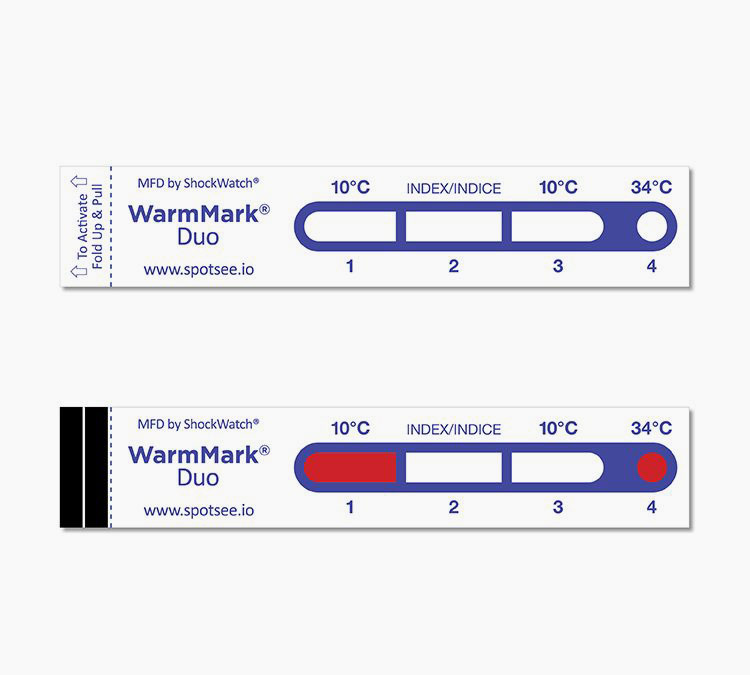

WarmMark is an ascending time-temperature indicator designed to visually show cumulative exposure to temperatures above a predefined threshold. Its operating principle is based on the migration of a red dye through one or more reading windows.

Once activated, the device cannot be reversed, making it one of the most widely used irreversible temperature indicators in the industry. The colour change from white to red acts as clear evidence of a temperature excursion.

WarmMark’s operation is divided into three key phases.

First, there is preconditioning and activation. Before use, the indicator must be kept for at least 30 minutes in an environment 5 °C below its activation temperature. It is then activated manually by removing a pull tab, which initiates the internal chemical process.

Secondly, when the indicator is exposed to temperatures above the threshold (±1 °C accuracy), the dye begins to move slowly. The speed of movement depends on both the temperature level and the exposure time.

There are different configurations:

- Short Run: Reading windows for brief, moderate or prolonged exposures.

- Long Run: Progressive lines showing the cumulative duration.

- Duo: Double threshold, with a second alert for higher temperatures.

- Mini: Compact versions for quick checks.

Finally, visual interpretation, which means that any pink or red hue indicates that the permitted limit has been exceeded. This information allows immediate criteria for product acceptance or rejection to be applied without the need for additional electronic equipment.

The use of WarmMark has a direct impact on supply chain efficiency. These industrial control devices make it possible to: reduce economic losses due to spoiled products, verify the effectiveness of thermal packaging, comply with thermal control regulations, and make quick decisions when receiving goods.

For this reason, its implementation is common in thermolabile medicines, vaccines, refrigerated products, and heat-sensitive goods.

Quality and logistics managers particularly appreciate the simplicity of WarmMark. Requiring no batteries, calibrations or software, these indicators are easily integrated into high-volume operations.

Furthermore, their irreversible nature provides a key advantage over other systems: the information cannot be manipulated or reset, reinforcing traceability and confidence in the thermal data obtained.

The market for passive temperature indicators continues to grow as a complement to digital systems. The combination of visual control devices with IoT solutions points to a hybrid model, where WarmMark acts as immediate physical proof of any thermal incident.

As regulatory requirements and the costs associated with product loss increase, technologies such as WarmMark will continue to play a strategic role in temperature control during transport and storage.

Understanding how WarmMark temperature indicators work is essential to ensuring the integrity of heat-sensitive products. Their simple design, reliability and irreversibility make them an essential tool in industrial control devices, especially in cold chains where every degree counts.

CONTACT US

We are characterised by our attention, flexibility, speed and delivery reliability. The best personalised service with a reliable supplier for regular deliveries.